Zero waste for multiple media

It can handle a series of flexible and rigid materials such as flexible film, coated banner, car sticker, high permeability film, reflective film, 3P fabric, KT board, cardboard, and polyvinyl alcohol in one pass. Besides, it has the remarkable characteristics of zero waste of printing media and no error in long-size printing.

Precise printing

No compensation calculations are needed – you can start printing immediately. No guiding cloth is required, which saves both media and labor. Switch between flexible and rigid media with one click, making one machine equivalent to multiple.

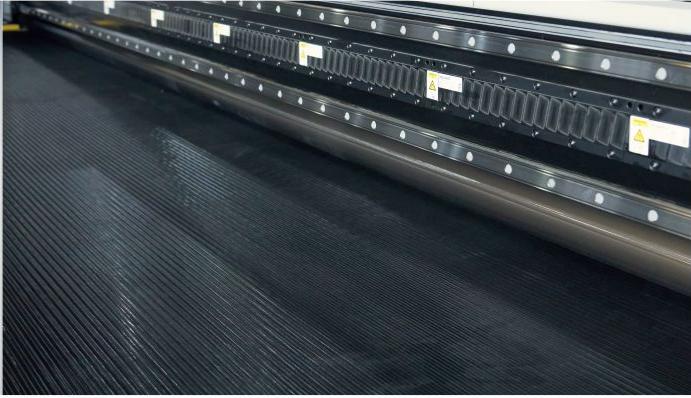

Four-zone intelligent vacuum adsorption system (standard)

The auto variable-frequency four-zone vacuum adsorption system prevents wrinkles on flexible media and warping on rigid media, simplifying the printing process.

Full-auto guide belt guiding system (standard)

The full-auto guide belt guiding system allows long-format printing without distortion or deviation, guaranteeing stable output quality.

Independent take-up and feeding system (optional)

The front and rear take-up and feeding system allows simultaneous handling of a 3.2m full roll or two 1.6m rolls, easily adapting to multiple specifications.

Rapid sheet positioning system (optional)

Front/rear buttons + sheet positioning enable one-click positioning for sheet printing and continuous operation, further improving efficiency.